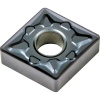

Carbide Inserts for Turning Inconel Waspaloy Nimonic Stellite Hi-temp AlloysCarbide Inserts for Turning Hi-temp Super-alloys Inconel Waspaloy Nimonic Stellite. Grade US05 (S05-M10 + Multi layer PVD Coating) Main application Hi-temperature Alloys, Inconel, Titanium Alloys and Stainless Steel under difficult conditions. Grade US15 (S15-M20 + Multi layer PVD Coating) Main application Hi-temp Alloys, Inconel, Titanium Alloys and Stainless Steel under difficult conditions. Grade 5115, Sub-micron Grain Carbide with special binder creating the strength required for Machining Super Alloys, Coating is TiAlN+TiN which helps to increase tool life under difficult conditions. Geometry 'FS' for Finishing to Fine Finishing High-temperature Alloys. Geometry GS for Medium to Roughing of High-temp Alloys. Chip Breaker Geometry 'MS' features a relativity sharp cutting edge with edge reinforcement providing stability at the cutting edge allowing for better feed rates and depth of cuts than normal on these types of materials. |